Our range of services

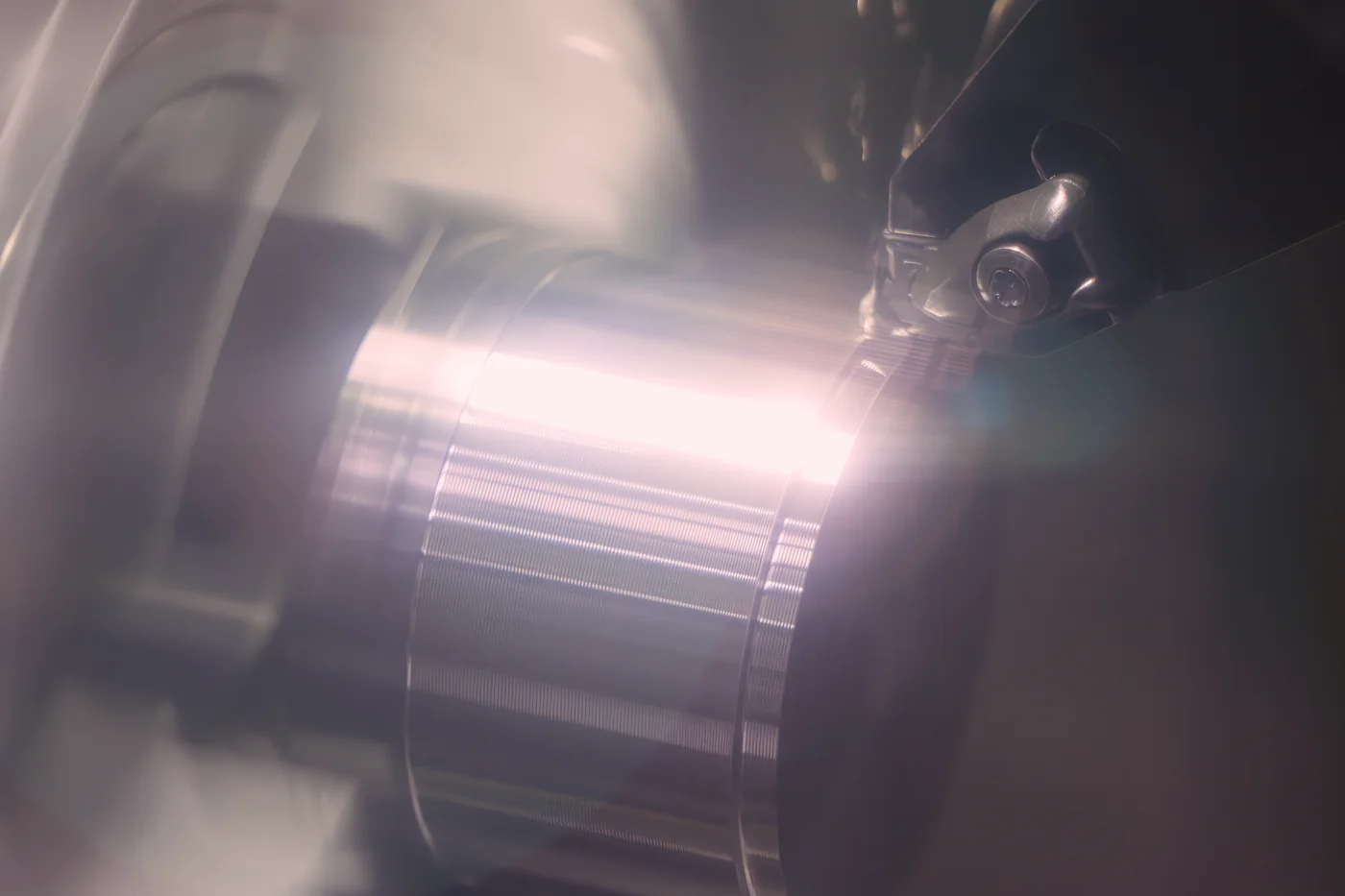

Highest precision

When manufacturing our products, we work with an accuracy of up to 2 micrometers.

Individuality

that convinces!

We develop customized solutions, from prototypes to large-scale production.

Passion &

Innovation

As specialists in mold and tool making, we give our customers a promise of quality.

Below you will find an overview of the different types of tools

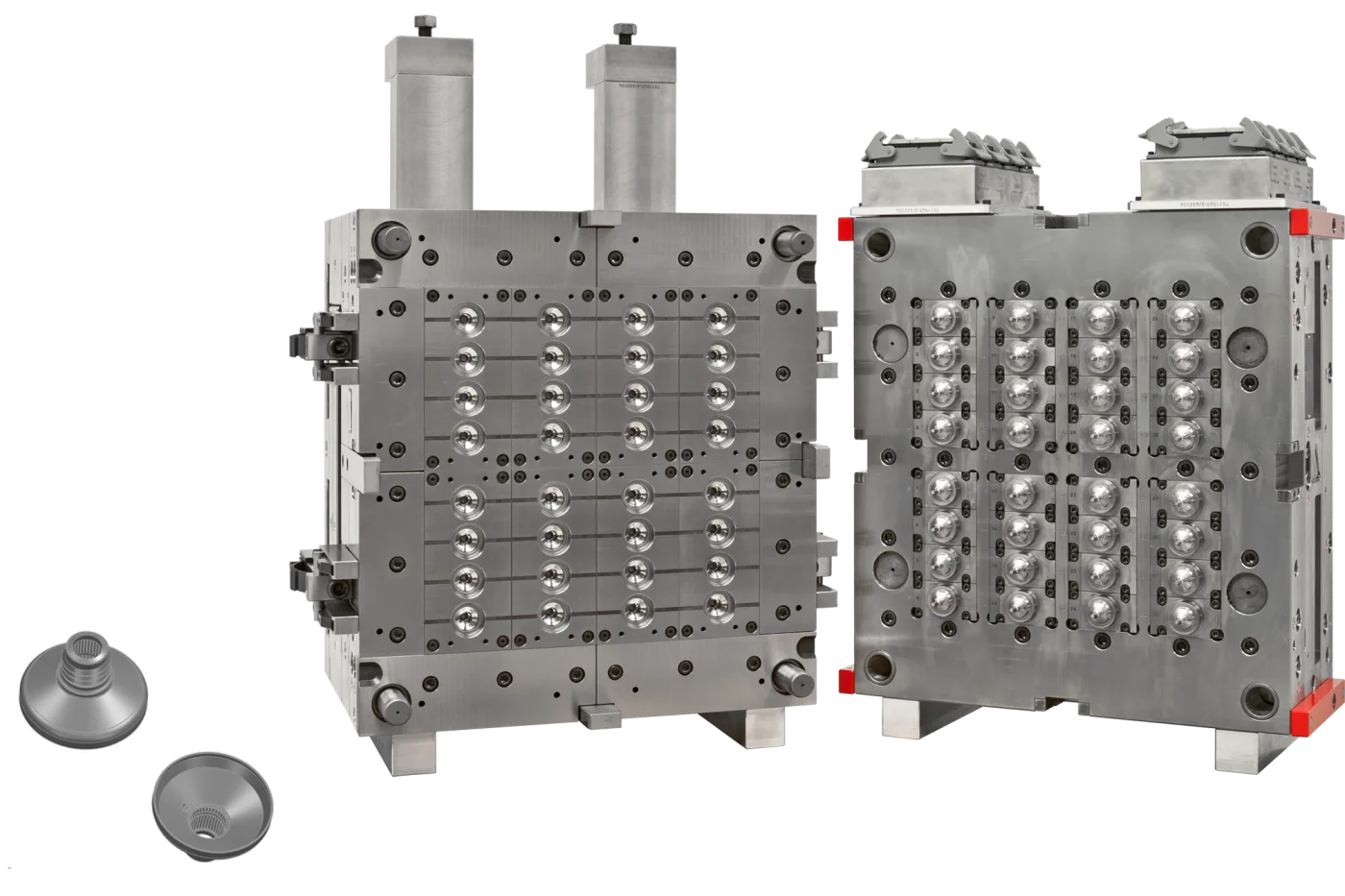

Standard injection mold 1K/48-cavity for razor component

- Full hot runner valve gate

- Single centered inserts

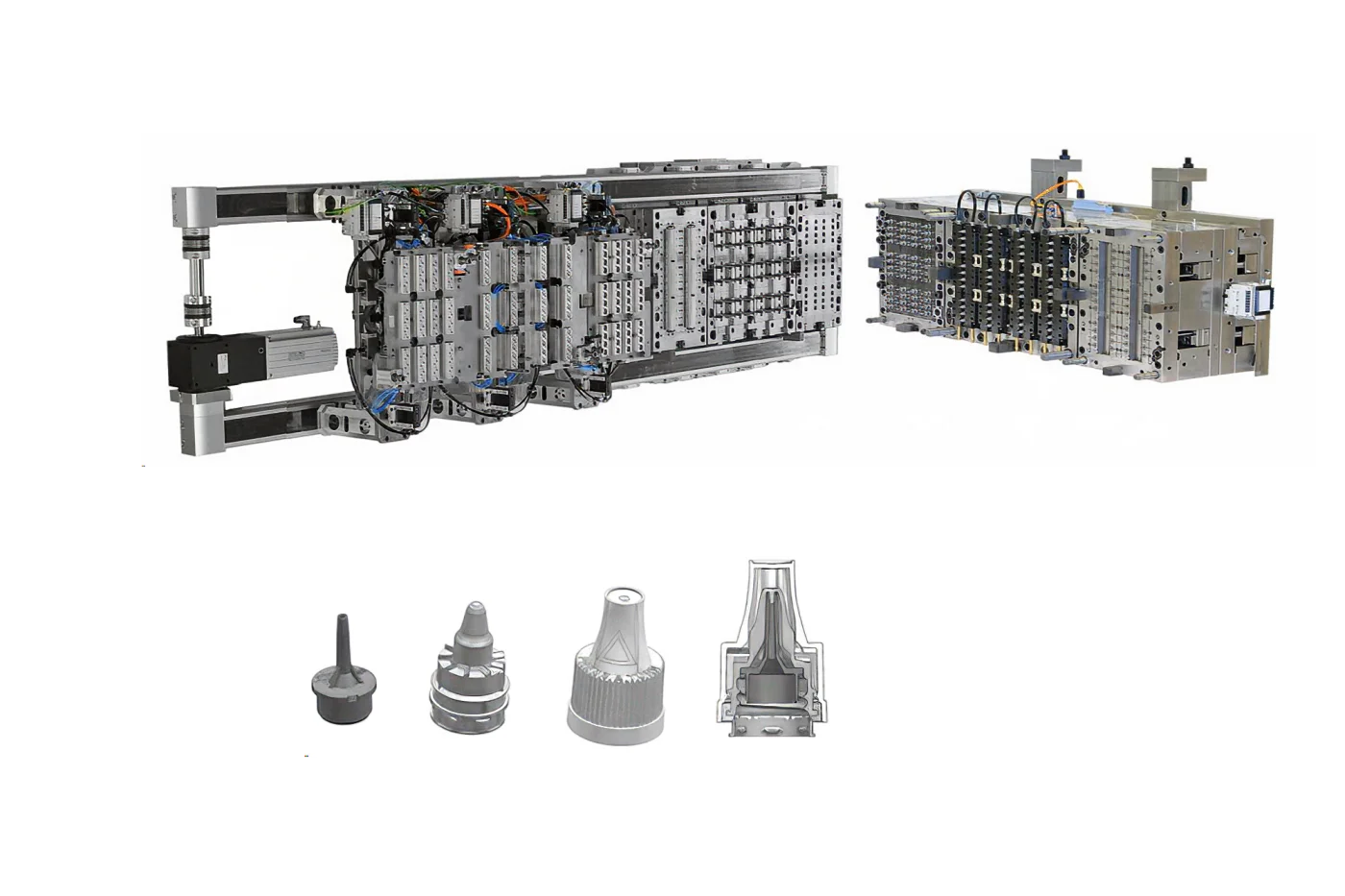

Standard injection mold 1K/32-cavity for tube shoulder

- Full hot runner open nozzle

- underfloor slide

Standard injection mold 1K/32+32-cavity for screw cap

- Full hot runner open nozzle

- stack mold

Injection molds for toothbrushes 1K,2K,3K

- Other Oral Care injection molds

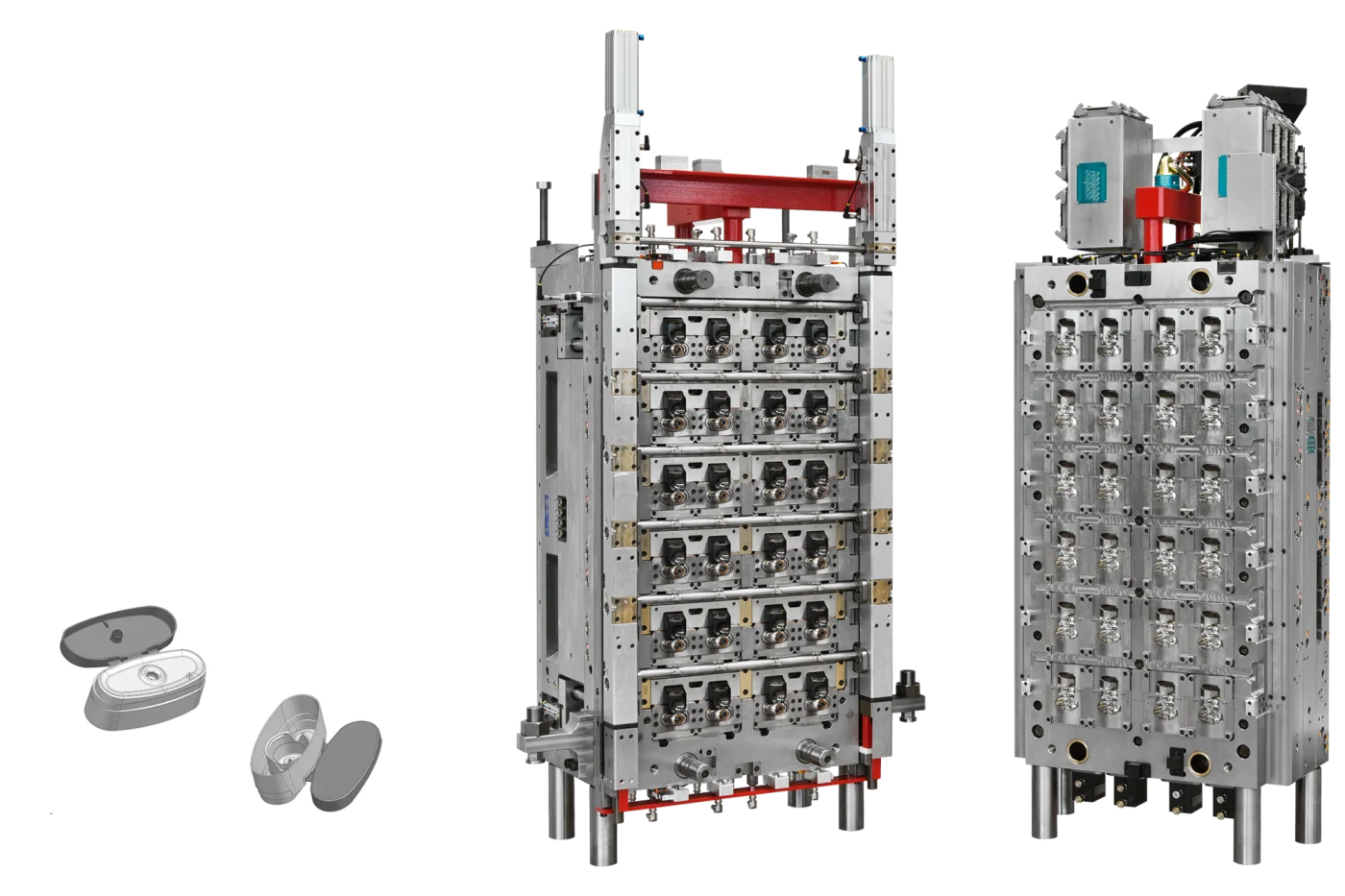

Injection mold with integrated 2K/2x24 valve gate for fliptop with core retraction

- Full hot runner valve gate

- Core retraction for valve gate separation body/lid

- with pneumatically driven in mold closure

- Plug contour bounced or thread de-spindled

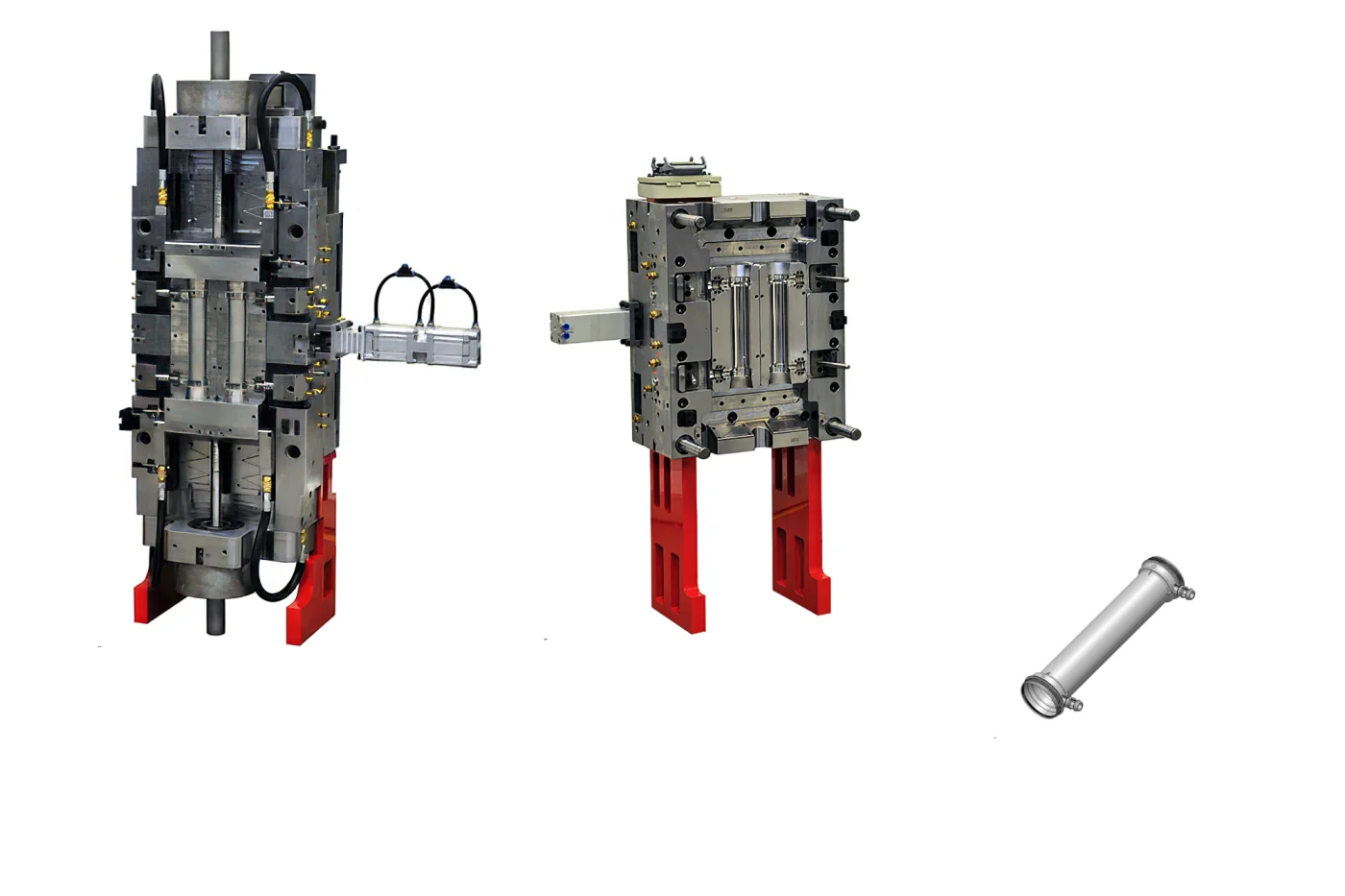

Special injection mold 1K/2-cavity for dialyzer tube

- Full hot runner valve gate

- with servo-electrically driven sliders

Special injection mold 1K/16-cavity for Fliptop

- Full hot runner open nozzle

- with side closure

- plug contour bounced or thread de-spindled

Special injection mold 1K/24-cavity for Fliptop

- Full hot runner open nozzle

- with pneumatically driven in mold closure

- plug contour bounced or thread de-spindled

Index plate injection mold 120° 2K/3x2-cavity for housing

- Full hot runner valve gate

- with electrically driven index plate

- with sliders on the nozzle side

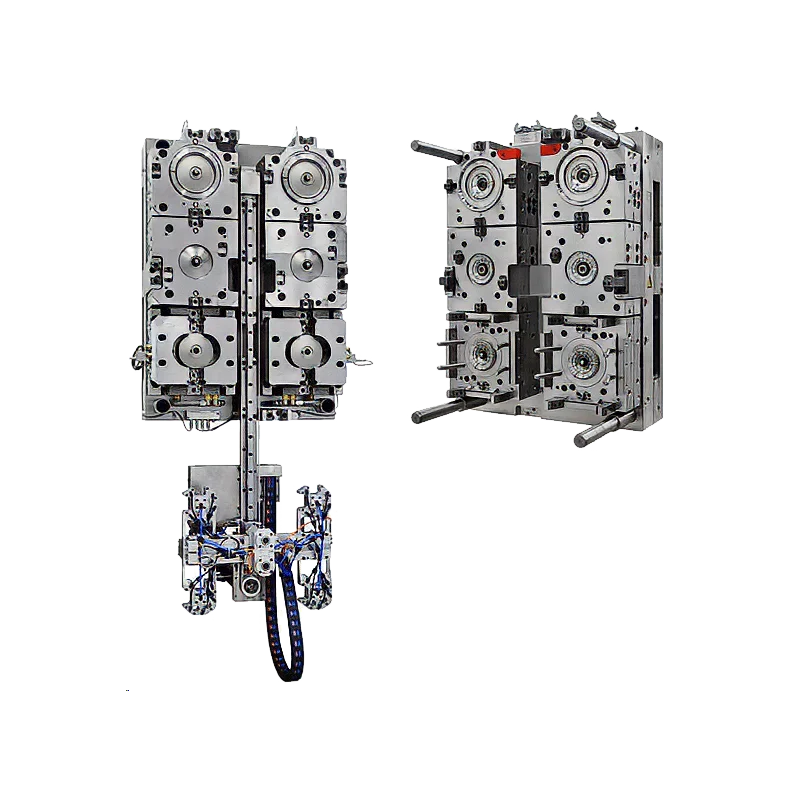

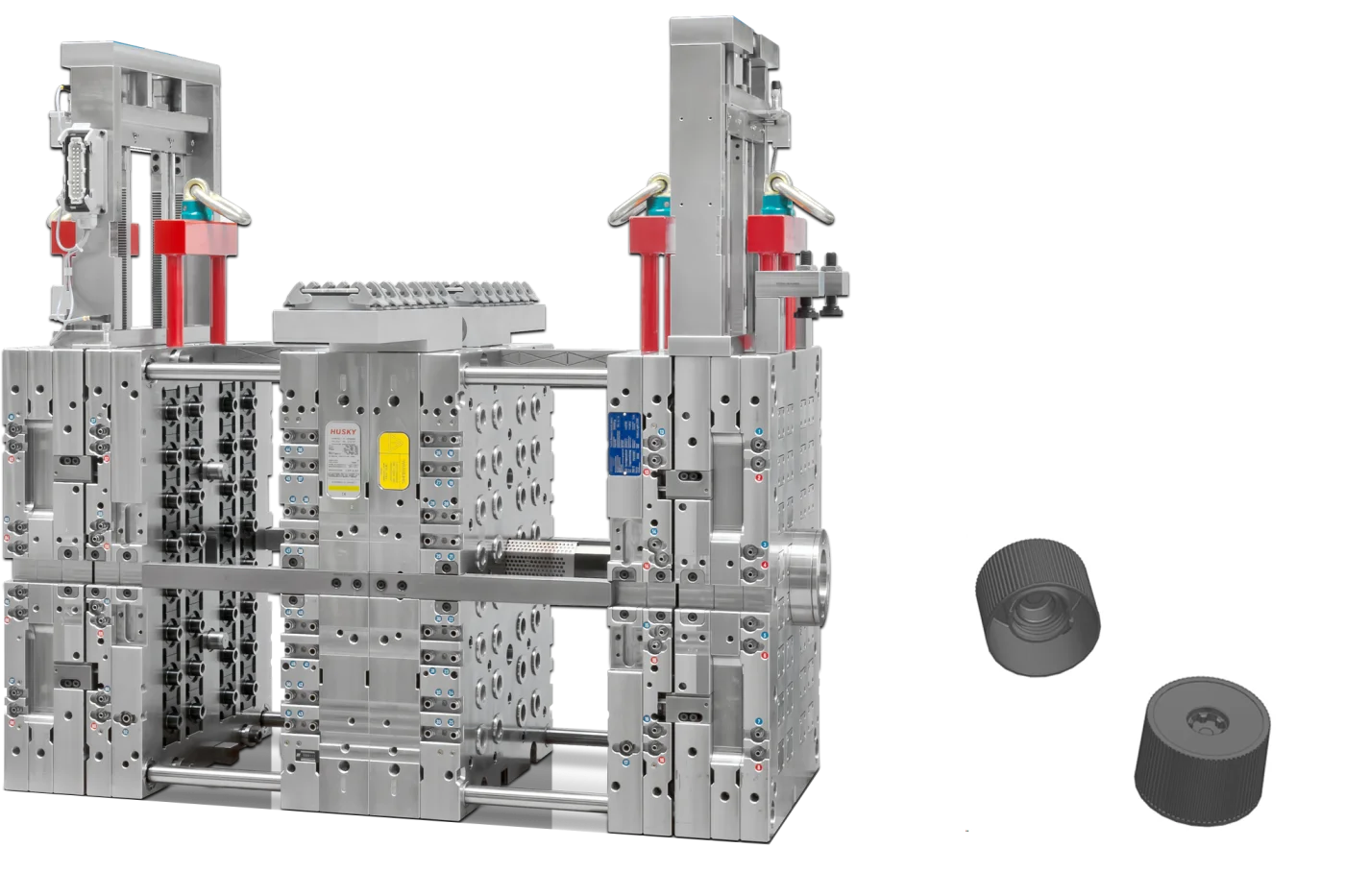

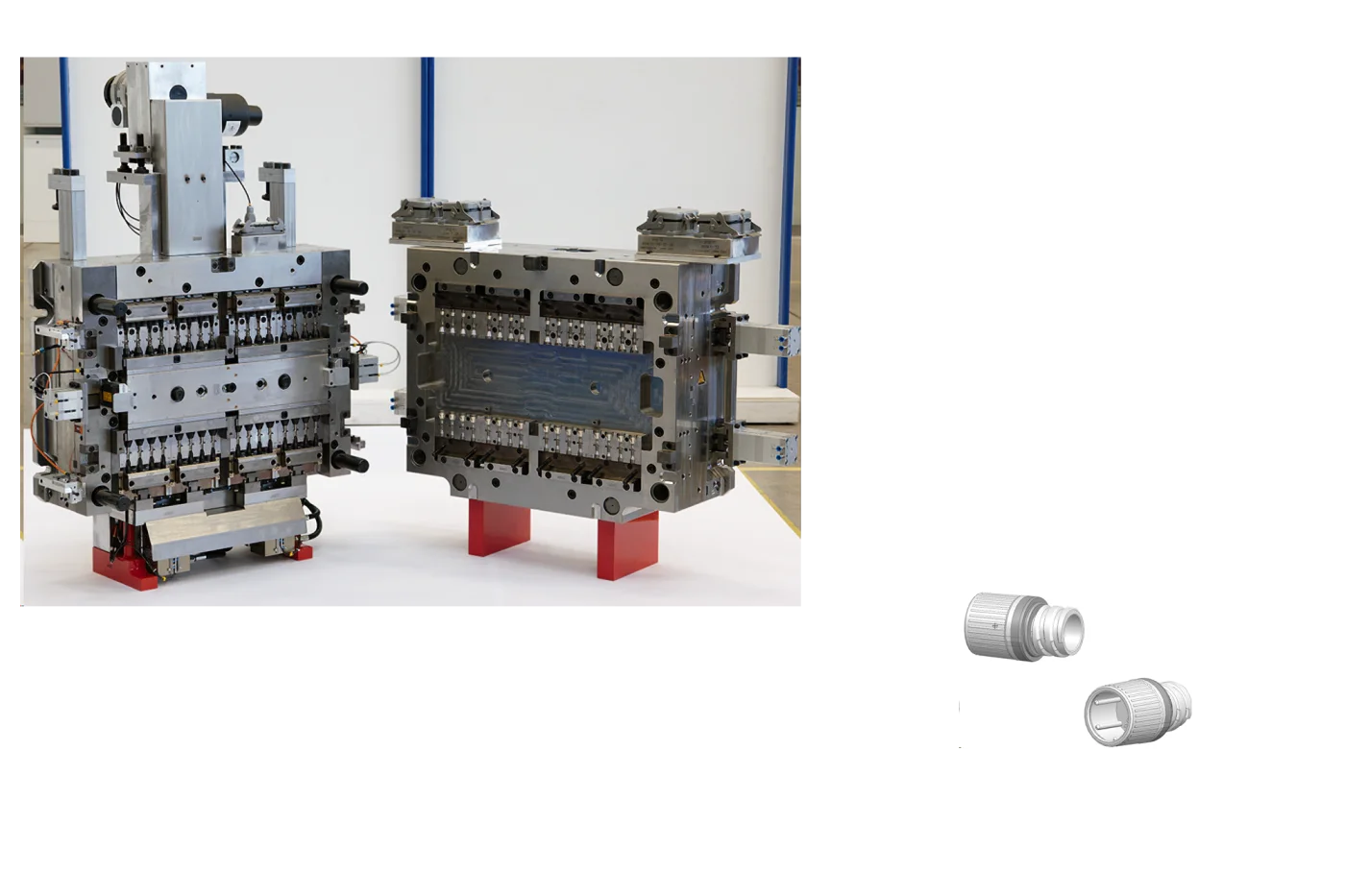

Index plate injection mold 180° 2K/2x16-cavity for medical component

- Full hot runner valve gate

- with electrically driven index plate

- with ejector-side slides

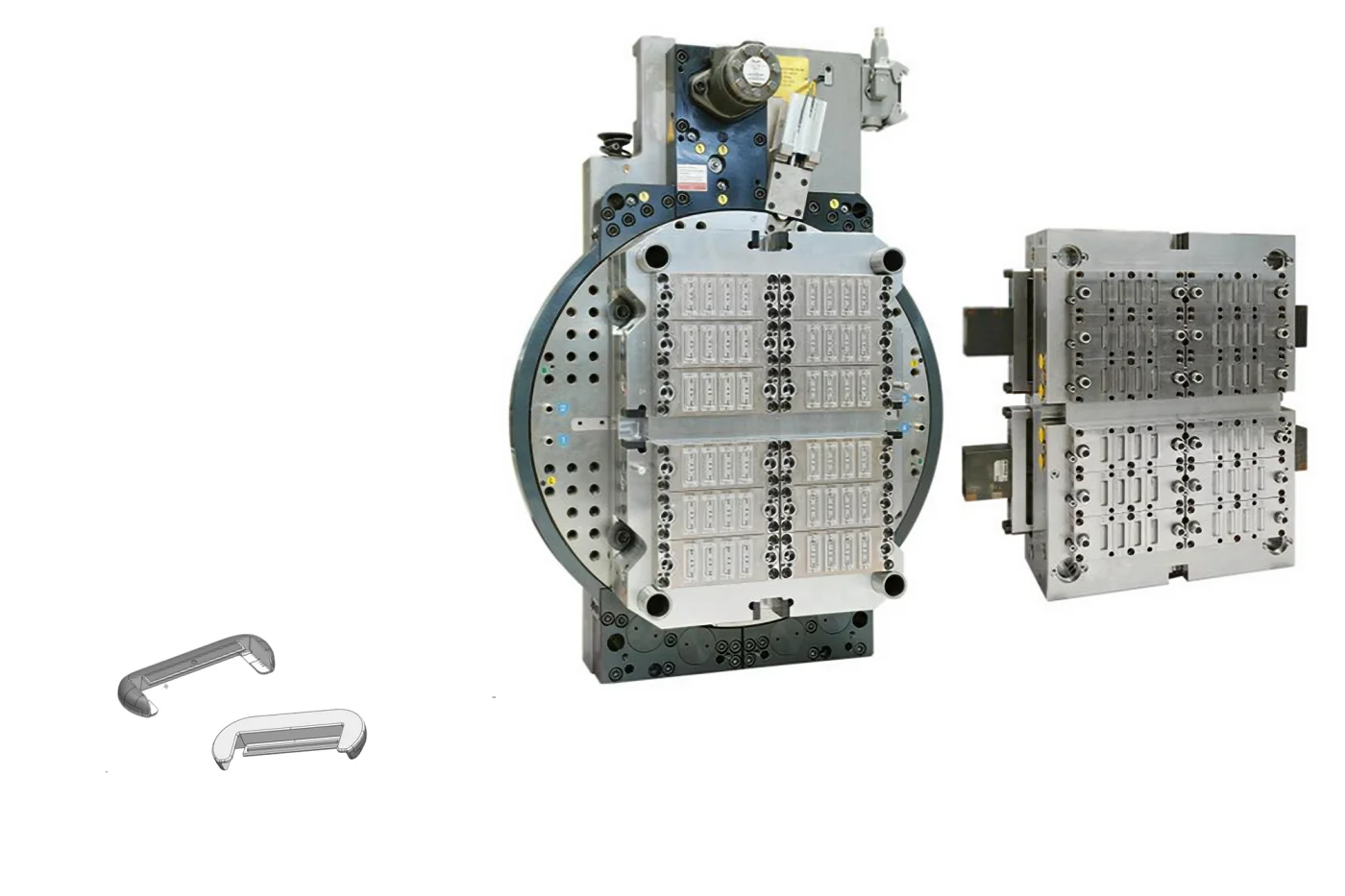

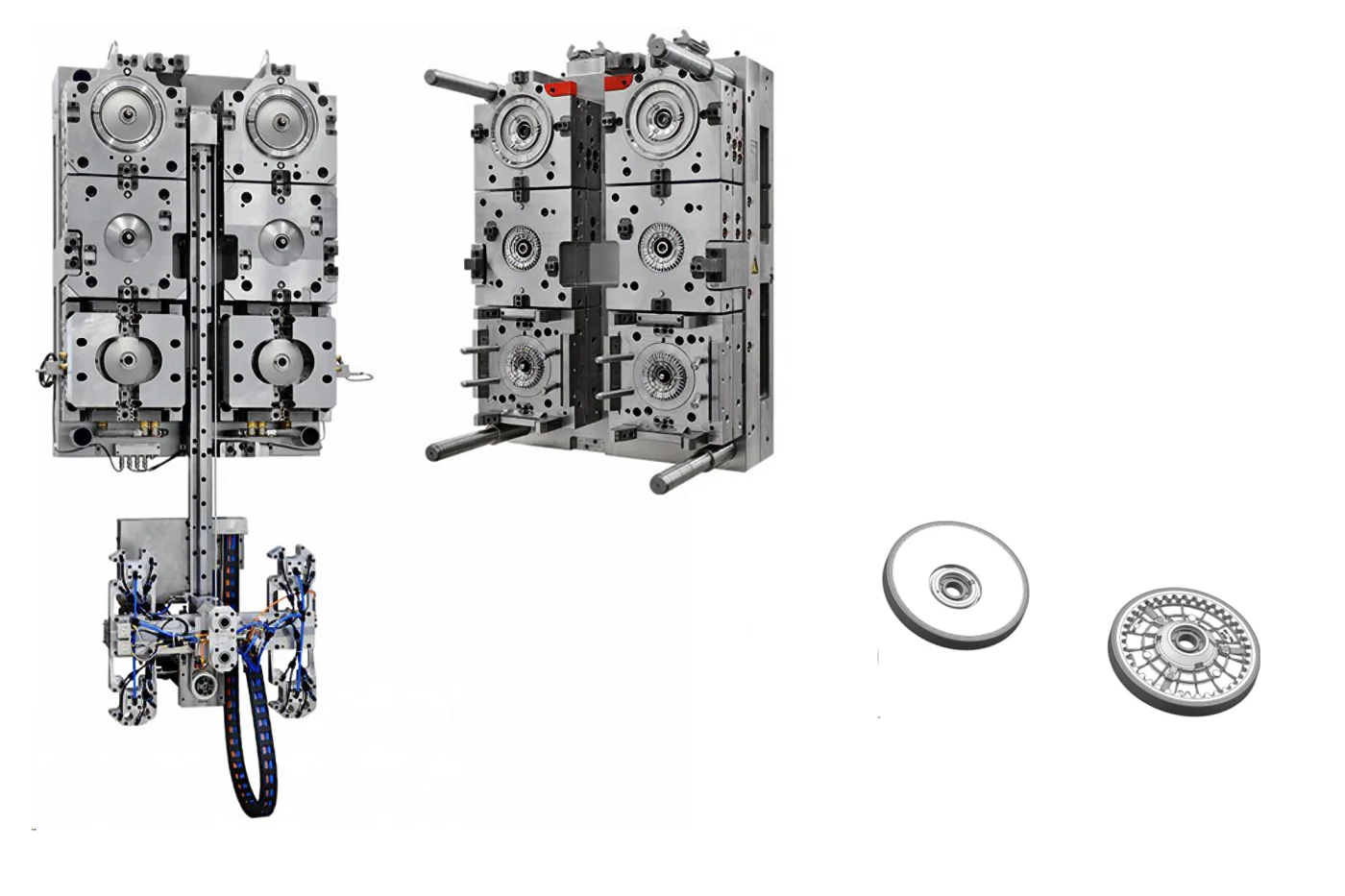

Turntable injection mold 180° 2K/2x24-cavity for razor component

- Full hot runner valve gate

- with external electrically driven rotary plate

- individually centered inserts

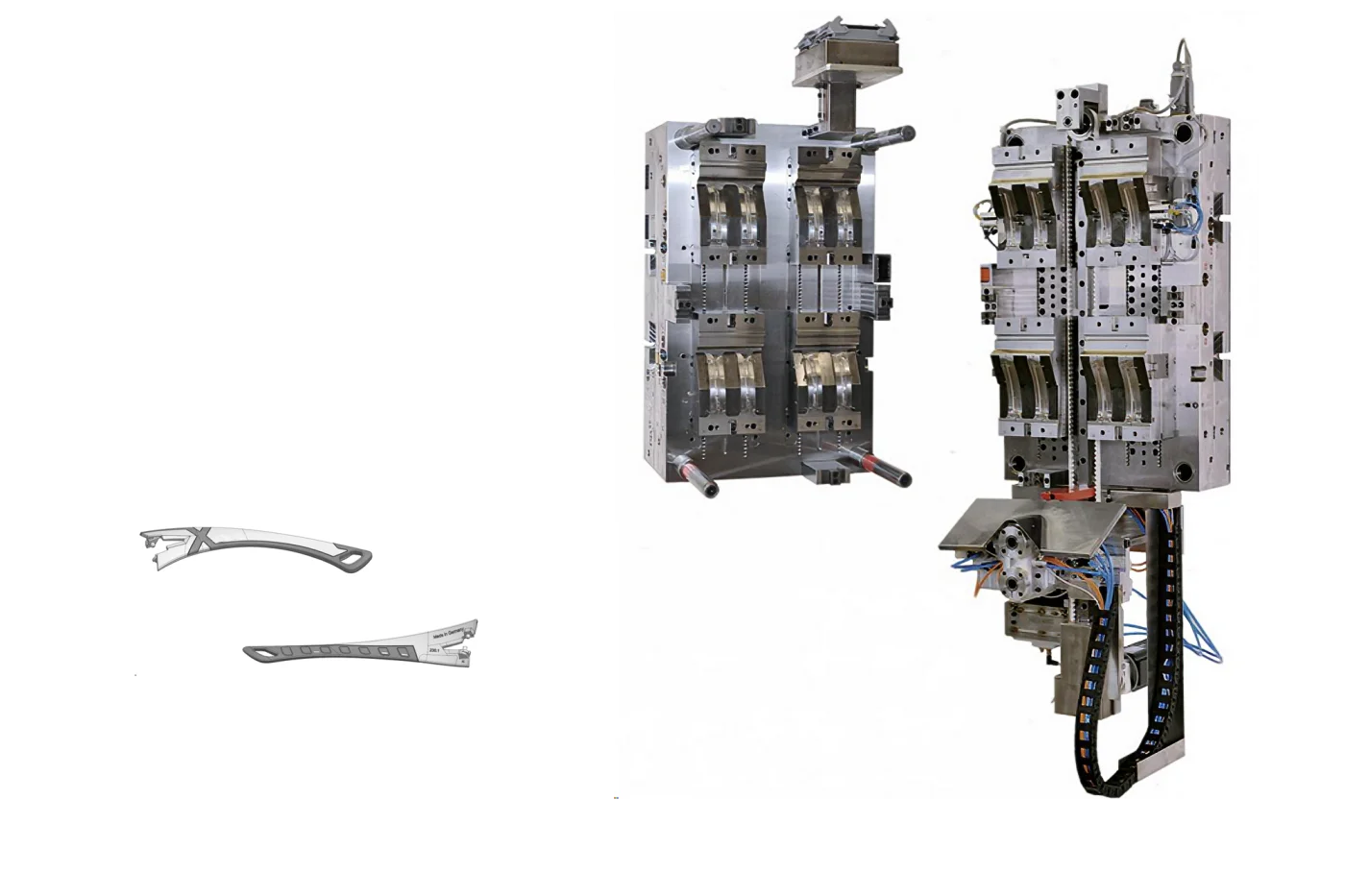

Injection mold with integrated handling 2K/2x4-cavity for spectacle temples

- Full hot runner valve gate

- with servo-electrically driven transfer handling

- Modular platform basis for different model variants

Injection mold with integrated handling 2K/3x2-cavity for wheel bodies with inserts

- Full hot runner valve gate

- with servo-electrically driven transfer handling

- Modular platform basis for different model variants

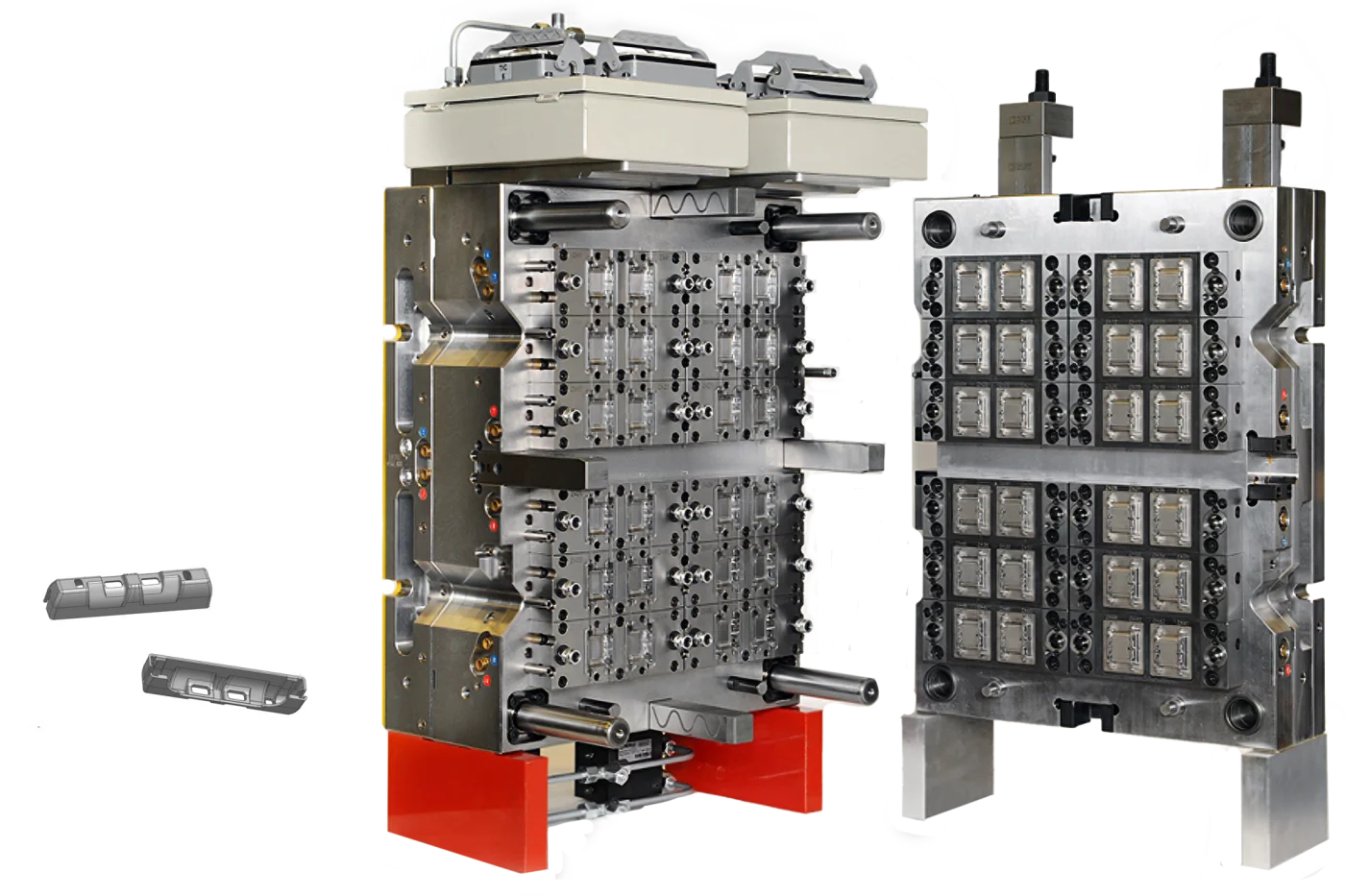

Injection mold with integrated handling and

Assembly station 3x1K/48+48+48-cavity for 3 valve gate components

- Full hot runner valve gate/side gate

- with servo-electrically driven transfer handling

- Handling picks up all 3 components simultaneously

- Assembly takes place parallel to the injection process

- Assembly and testing station directly next to the machine